Anomaly Detection

Easily identify anomalies with only normal images, all on edge devices

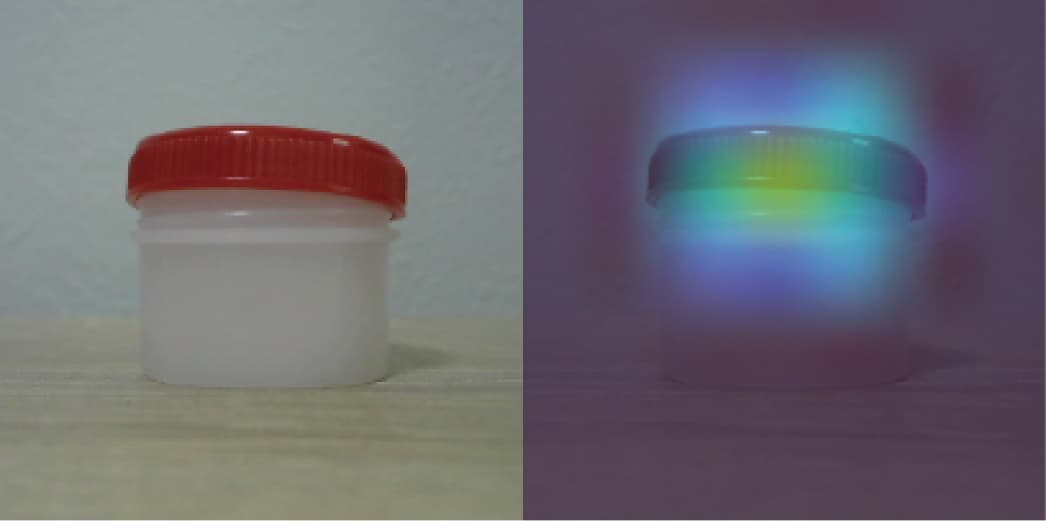

Using feature data extracted from images captured by cameras, the model detects anomalies within those images. By learning the distribution of feature data from a small set of normal images and comparing them with the distribution of feature data from new images, it identifies abnormal areas. Our approach exclusively utilizes normal images for training, eliminating the need for manual annotation and enabling the detection of unknown anomalies. Only a few dozen to around 100 images* are required for training. (*The number of images required for training depends on the level of variability of the normal images.)

Product Inquiry

Normal

Anomaly

USE CASE

Defective detection on Production and /or Inspection process

By using compact device equipped with AI-powered smart cameras for visual inspections, it can be placed on the production and inspection lines within the factory. This allows for the detection of defective items directly on the lines. The device itself is capable of AI learning, ensuring that sensitive product images do not need to be shared externally due to its ability to perform learning tasks independently.

Foreign object inspection

With the ease of conducting AI training on-site, it is now possible to perform inspections on objects with individual variations, such as food items. AI-based learning can be done in real time, allowing for immediate inspections. Additionally, it can detect previously unknown foreign objects that were not present during the AI training phase. This capability extends to inspections on multi-product manufacturing lines as well.

Smoke detection in unmanned facilities

By leveraging surveillance cameras, this instantly detects anomalies caused by smoke in the video feed. it enables rapid initial fire suppression, as well as the evacuation of individuals and protection of assets without waiting for smoke sensors to detect smoke concentration in facilities.

Color inspection

It detects subtle differences in color shades from color samples, making it useful for tasks like inspecting paint quality. This capability aids in the discovery of color variations that are imperceptible to the human eye without direct side-by-side comparison, helping to ensure product specifications are met.

APPLICATIONS

IMAGE PROCESSING

Image Noise Reduction

AI technology that reduces high-ISO noise caused by low-light shooting to achieve high image quality

Video Noise Reduction

AI technology to achieve high image resolution in real-time for video recording where long-second exposures are difficult to use

Super Resolution

AI technology to enhance low-resolution digital images while preserving sharpness

Deblurring

AI technology to reduce blur caused by camera shaking or shooting moving subjects

Deraining

AI technology to remove water drops on the surface of the camera lens from the image after shooting

IMAGE RECOGNITION

Object Detection

AI technology to detect where people, vehicles, and other objects are located in an image

Segmentation

AI technology to divide colors by object areas

Pose Estimation

AI technology to estimate the position of human joints and major points (neck, shoulders, elbows, wrists, ankles, etc.) and their connections

Classification

AI technology to recognize objects in images and classify them

Anomaly Detection

Detects anomalies by training only normal images